The New evo2 Automatic Crane Hook

Same core, smarter and more compact

Since we invented the automatic hook in 2006, our customers have identified the need for smaller, lighter and more compact crane hooks.

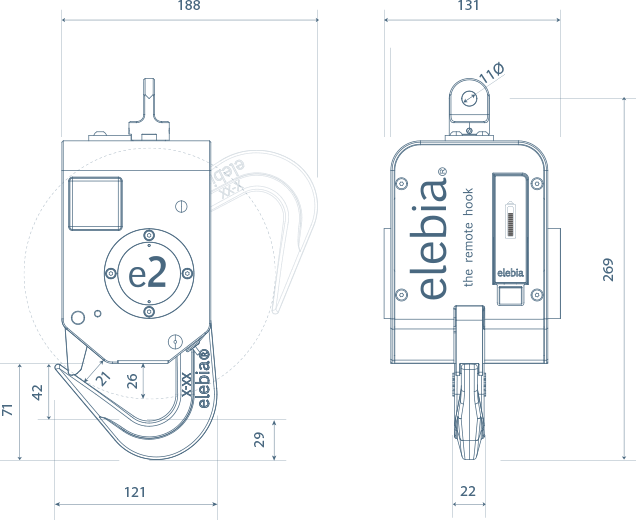

Having listened, we are now proud to present the evo2 automatic hook. Weighing only 7 kg./15.43 lbs. and with a working load limit of 2,500 kg./5,511 lbs., the evo2 remote release hook has additional features than its bigger counterparts. Smaller, more compact, lighter, more efficient, more versatile… Smarter!

The evo2 is an automatic crane hook which, like the rest of the range of our lifting hooks for cranes, hooks on and releases the load remotely, increasing safety, productivity and comfort of all cargo lifting operations.

Our smallest automatic crane hook lifts and releases the load remotely. The remote controlled crane hook generates a magnetic field that attracts and orients the sling, masterlink or rigging gear. The operator then presses the “close” button on the remote control to automatically close the crane hook, without any manual intervention, operating remotely from a safe distance.

elebia leads the way towards the future of automatic crane hooks.

Efficient (3 hour charge = 1 week's power)

The evo2 battery is smaller and lighter than the rest of the range of safety hooks. With the new Eink charge status display system and new electronics, autonomy and consumption are optimized.

Swivel with Bearings

The bearings allow the hook to rotate freely. The operator can lock it at every 90º position.

Clutch Protected Motor

The new evo2 automatic crane hook has its motor clutch protected. Thanks to this innovation, impacts on the automatic hook will not be transmitted to the motor extending its lifespan.

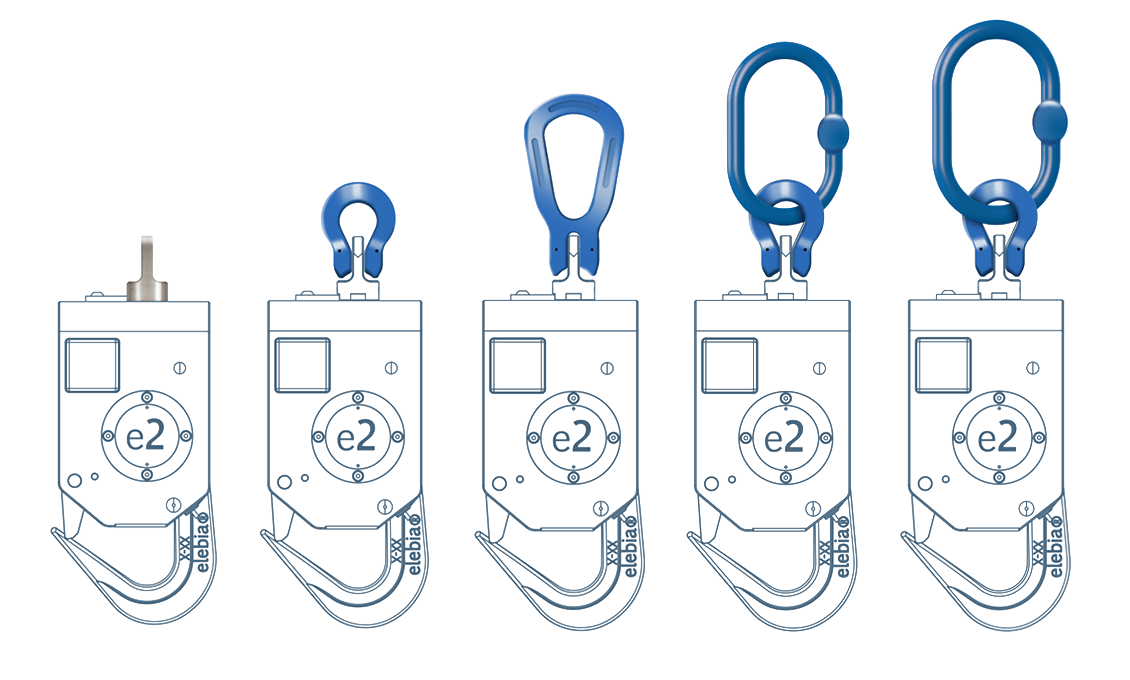

Top Link

The system that links the automatic hook with the crane can be customized in order to adapt itself to any kind of situation.

Fail-safe Design

Just like the rest of our bigger automatic hooks, the evo2 is designed under a that makes it impossible to drop a suspended load. Due to its geometry and its motor, the safety hook will never drop the load if it’s not placed correctly on a horizontal surface.

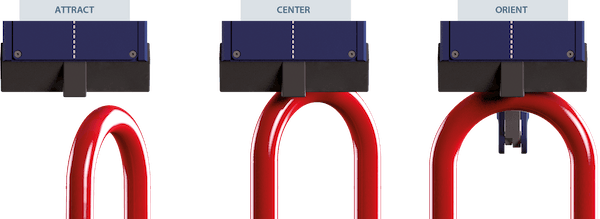

Magnetic System

The elebia crane hooks come with a unique magnetic system, formed by 32 neodymium permanent magnets. These magnets are placed in a precise configuration that generate an oriented magnetic field with 3 functions: attract, center and orient the masterlink. This basic component, which is present in all our remote hooks, is what allows the remote engage of loads.

Some other options are available to be configured:

Encoder

The evo2 automatic hook incorporates an innovative position encoder. This allows the user to know the exact position of the crane hook, allowing better control. This results in longer motor life and safer operations. The sensor is contactless: no wearings and zero maintenance.

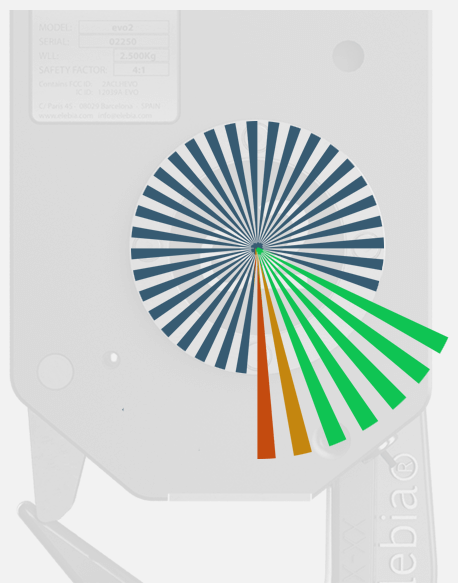

Weighing Scale

The complete range of automatic crane hooks can be upgraded with a load cell to weigh the load that is being lifted. This cargo cell is precise, reliable, compact and fully integrated into the safety hook, representing no increase in weight or dimensions of the unit. The load cell is recommended for preventing overloads and for load control. Load cells can also be retrofitted into older models of our hooks.

The load cell in combination with the eMAX remote control transforms all of our crane hooks into a precise weighing scale with advanced features.

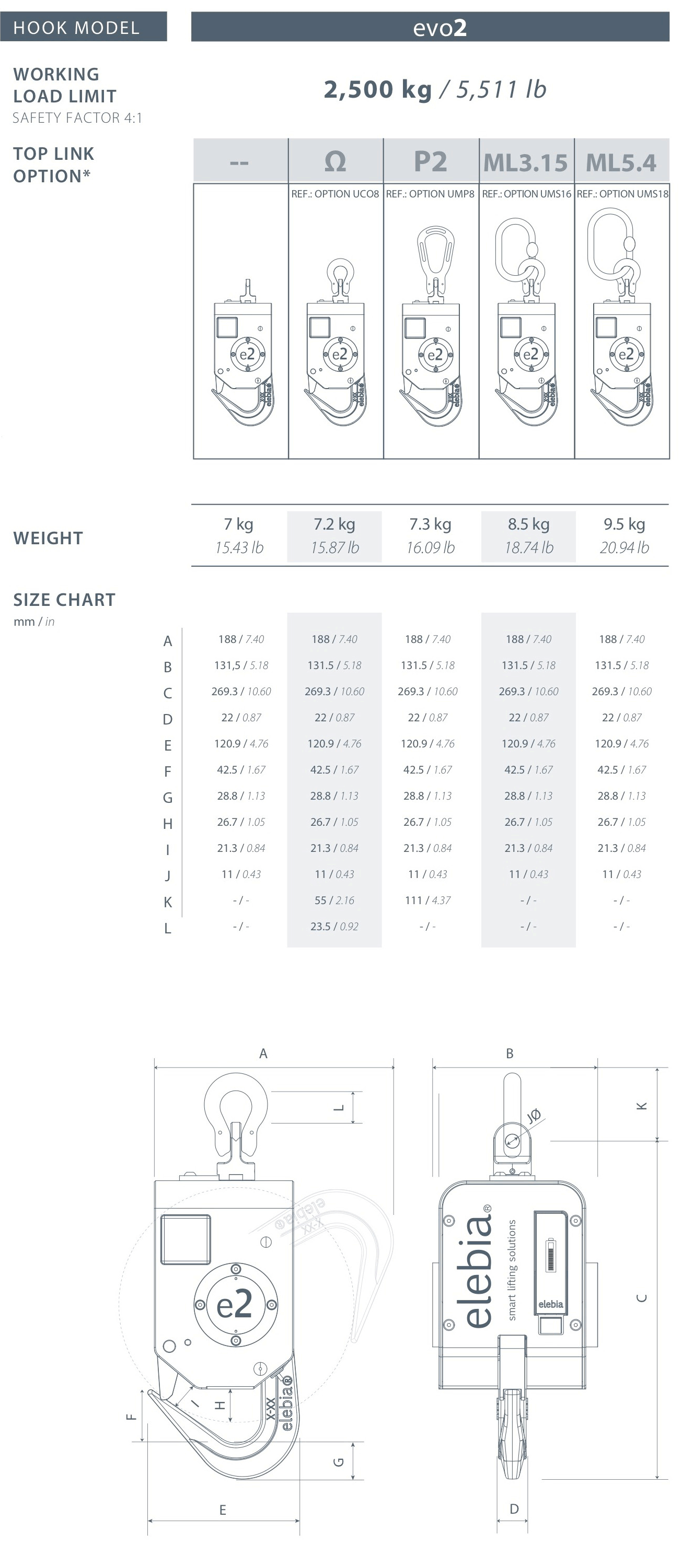

Specification

2,500 Kg / 5.511lbs

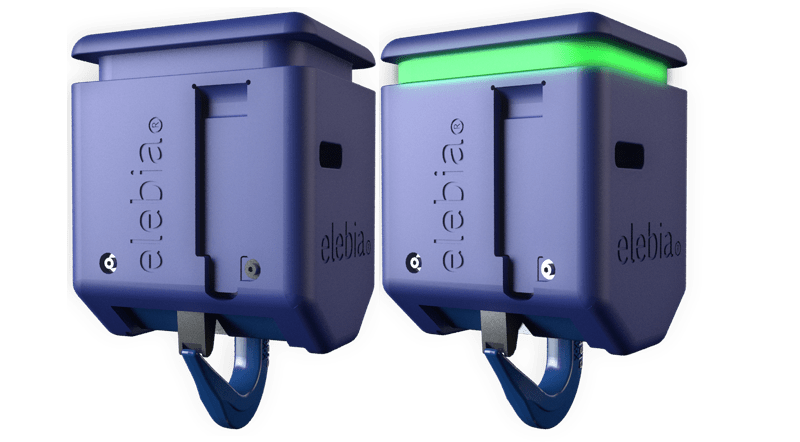

evo2 Bumpers

The bumper for the automatic crane hooks is the perfect shock absorber that protects the safety hooks from impacts.

With safety always in mind, the new evo2 Bumpers which protect the lifting hooks for cranes from impacts now also carry a LED status indicator, which shows the lifting hook’s status at all times with a high-brightness 4 colour colour-code scheme visible from the operator’s position.

– Protect the hook and your load from day-to-day wear.

– Protect workers in case of impact.

– Extend product life.

– Reduce maintenance costs.

New evo2 Bumper and Bumper with LEDs

Remote Controlled

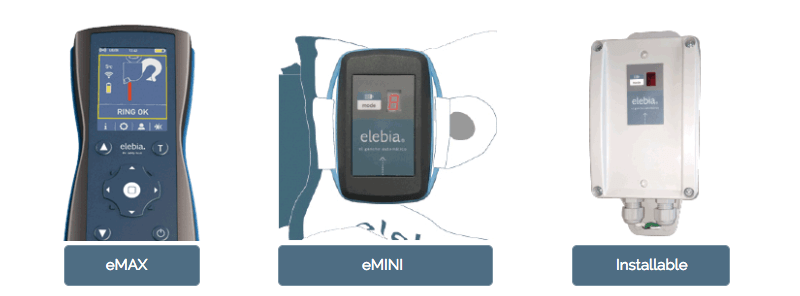

Open and close the safety hook or receive real-time information of weight, battery level, and other values of the lifting operation.

Just like our lifting hooks for bell furnaces and automatic lifting clamps, the automatic crane hooks can be paired to any of our remote controls.

Special Environments

The standard automatic hook units are rugged, designed and built to work in almost

every industry. For special environments, you have the following options:

Marine

C5M Painting and AISI components.

Recommended for:

Marine Environments

Industries:

Offshore Wind Turbines, Onboard Cranes, Buoys

DNV

DNV 2.22 certification for Offshore lifting appliances.

Recommended for:

Offshore Operations

Industries:

Offshore Wind Turbines, Onboard Cranes

ATEX/IECEx

Units with IECEx certification for zones 1 & 21 according to European Directive 2014/34/EU and IECEx international standards.

IECEx certification to work on sites classified as zone 1 & zone 21 according to the European Directive 99/92/EC and IECEx international standards.

Recommended for:

Operations in potentially explosive atmospheres

Industries:

Oil & Gas, Mining & Chemical

Heat Shield

Heat shield that protects the automatic hook and its electronic components from radiated heat and extended temperature working range.

Recommended for:

Operations where the automatic hooks are subject to extremely elevated temperatures and radiated heat

Industries:

Foundries