SPUR GEAR SERIES WINCHES

Up to 907kg Capacity

When you need to lift, lower or position a heavy load, Thern’s spur gear hand winches are designed to deliver excellent performance and long life, no matter what your application.

QUICK FACTS

- Up to 2000 lb (907 kg) capacity

- Machine-cut spur gears

- Variety of configurations

- Stainless steel models available

- Corrosion resistant

- Two-Year Limited Warranty

SERIES MODELS

- M401

- M4022/M4022PB

- M4032/M4032PB

- M4042PBSS

- M4312/M4312PB

- M4312PBSS

- M4412/M4412PB

Features

Machine Cut Spur Gears

For accurate and long lasting service.

Automatic Brake Models

Provide positive load control for lifting and lowering operations. Brake models have PB or B suffix.

Corrosion Resistant

Trivalent zinc plated finish protects against corrosion in harsh environments.

Quick Disconnect Anchor

For quickly attaching or removing wire rope equipped with a swaged ball fitting.

Bronze and Radial Ball Bearings

Provide smooth and efficient operation.

Large Diameter Drums

Minimize wear to extend wire rope life.

Gear Covers

Protect gears and help prevent injuries.

Stainless Steel Models Available

For harsh environments. See models with SS suffix. Stainless steel models are electro-polished for added corrosion resistance.

Two-Year Warranty

Industry-leading two-year limited warranty on all our products

Accessories / Options

Vertical Lead Block

The Redline Series is used to change the direction of the rope, so the winch can be mounted in a convenient location and the Redline Lead Block will control the path of the rope to avoid obstacles, reduce hazard, and improve rope wear.

Wire Rope Assemblies

rope-assemblies-500Galvanized or stainless steel wire rope assemblies, available in various lengths.

Performance Specs.

| Spur Gear Hand Winches Performance Characteristics — Metric | ||||||||||||

| Load Rating | Drum Capacity ² | |||||||||||

| Model No. | Description | 1st Layer | Mid Drum | Full Drum | Wire Rope Dia.1 | 1st Layer | Mid Drum | Full Drum | Sgl Gear Ratio | Dbl Gear Ratio | Force3 to Lift 453.5 kg | Approx. Ship Wt. |

| (kg) | (kg) | (kg) | (mm) | (m) | (m) | (m) | (kg) | (kg) | ||||

| M401 | 226.7 kg — marine duty | 226.7 | 181.4 | 136.0 | 3.1 | 2.1 | 18.2 | 39.6 | — | — | — | 3.6 |

| (for pulling only) | 4.7 | 1.2 | 8.2 | 18.2 | ||||||||

| M4022 | 453.5 kg — marine duty | 453.5 | 317.5 | 226.7 | 3.1 | 1.2 | 15.8 | 39.6 | 2.85:1 | — | 18.1 | 5.4 |

| (for pulling only) | 4.7 | 0.9 | 7.9 | 17.3 | ||||||||

| M4022PB | 453.5 kg — marine duty | 453.5 | 317.5 | 226.7 | 3.1 | 1.2 | 15.8 | 39.6 | 2.85:1 | — | 18.5 | 7.7 |

| (for pulling only) | 4.7 | 0.9 | 7.9 | 17.3 | ||||||||

| M4032 | 453.5 kg — marine duty | 453.5 | 317.5 | 226.7 | 3.1 | 3.3 | 33.5 | 76.2 | 2.85:1 | — | 18.1 | 6.3 |

| (for pulling only) | 4.7 | 2.1 | 15.5 | 33.5 | ||||||||

| M4032PB | 453.5 kg — marine duty | 453.5 | 317.5 | 226.7 | 3.1 | 3.3 | 33.5 | 76.2 | 2.85:1 | — | 18.5 | 8.1 |

| (for pulling only) | 4.7 | 2.1 | 15.5 | 33.5 | ||||||||

| M4042PBSS | 453.5 kg — stainless steel | 453.5 | 362.8 | 272.1 | 3.1 | 3.6 | 33.5 | 73.1 | 3.83:1 | — | 20.8 | 10.8 |

| with brake (for lifting) | 4.7 | 2.4 | 14.6 | 33.5 | (sgl gear) | |||||||

| 6.3 | 1.5 | 8.2 | 17.9 | |||||||||

| M4312 | 907.1 kg — marine duty | 907.1 | 725.7 | 544.3 | 4.7 | 2.4 | 14.6 | 33.5 | 3.83:1 | 14.7:1 | 9.0 | 10.4 |

| (for pulling only) | 6.3 | 1.5 | 8.2 | 17.9 | (dbl gear) | |||||||

| 7.9 | 1.2 | 5.1 | 11.8 | |||||||||

| M4312PB | 907.1 kg — marine duty | 907.1 | 725.7 | 544.3 | 4.7 | 2.4 | 14.6 | 33.5 | — | 14.7:1 | 7.7 | 12.7 |

| with brake (for lifting) | 6.3 | 1.5 | 8.2 | 17.9 | (dbl gear) | |||||||

| 7.9 | 1.2 | 5.1 | 11.8 | |||||||||

| M4312PBSS | 907.1 kg — stainless steel | 907.1 | 725.7 | 544.3 | 4.7 | 2.4 | 14.6 | 33.5 | — | 14.7:1 | 7.7 | 12.7 |

| with brake (for lifting) | 6.3 | 1.5 | 8.2 | 17.9 | (dbl gear) | |||||||

| 7.9 | 1.2 | 5.1 | 11.8 | |||||||||

| M4412 | 907.1 kg — marine duty | 907.1 | 725.7 | 544.3 | 4.7 | 5.4 | 29.5 | 64.0 | 3.83:1 | 14.7:1 | 9.0 | 11.3 |

| (for pulling only) | 6.3 | 4.2 | 15.8 | 36.5 | (dbl gear) | |||||||

| 7.9 | 3.3 | 10.6 | 23.4 | |||||||||

| M4412PB | 907.1 kg — marine duty | 907.1 | 725.7 | 544.3 | 4.7 | 5.4 | 29.5 | 64.0 | — | 14.7:1 | 7.7 | 13.6 |

| with brake (for lifting) | 6.3 | 4.2 | 15.8 | 36.5 | (dbl gear) | |||||||

| 7.9 | 3.3 | 10.6 | 23.4 | |||||||||

Please contact factory or nearest Thern distributor for firm fixed price and delivery. 1 For Models M4022, M4022PB, M4032, M4032PB ball end is available for 3.1 mm and 4.7 mm only. 1 For Models M4042PBSS, M4312, M4312PB, M4312PBSS, M4412, M4412PB ball end is available for 4.7 mm and 6.3 mm only. 2 Actual drum capacities may be 25-30% less, due to nonuniform winding. Wire rope tension will also affect drum capacity. 3 Approximate handle force required to lift 453.5 kg with an empty drum and maximum handle length.

IMPORTANT: It is the owner’s or operator’s responsibility to determine the suitability of the equipment to its intended use. Study all applicable codes, manuals and regulations. Be sure to read the Owner’s Manual supplied with the equipment before operating it.

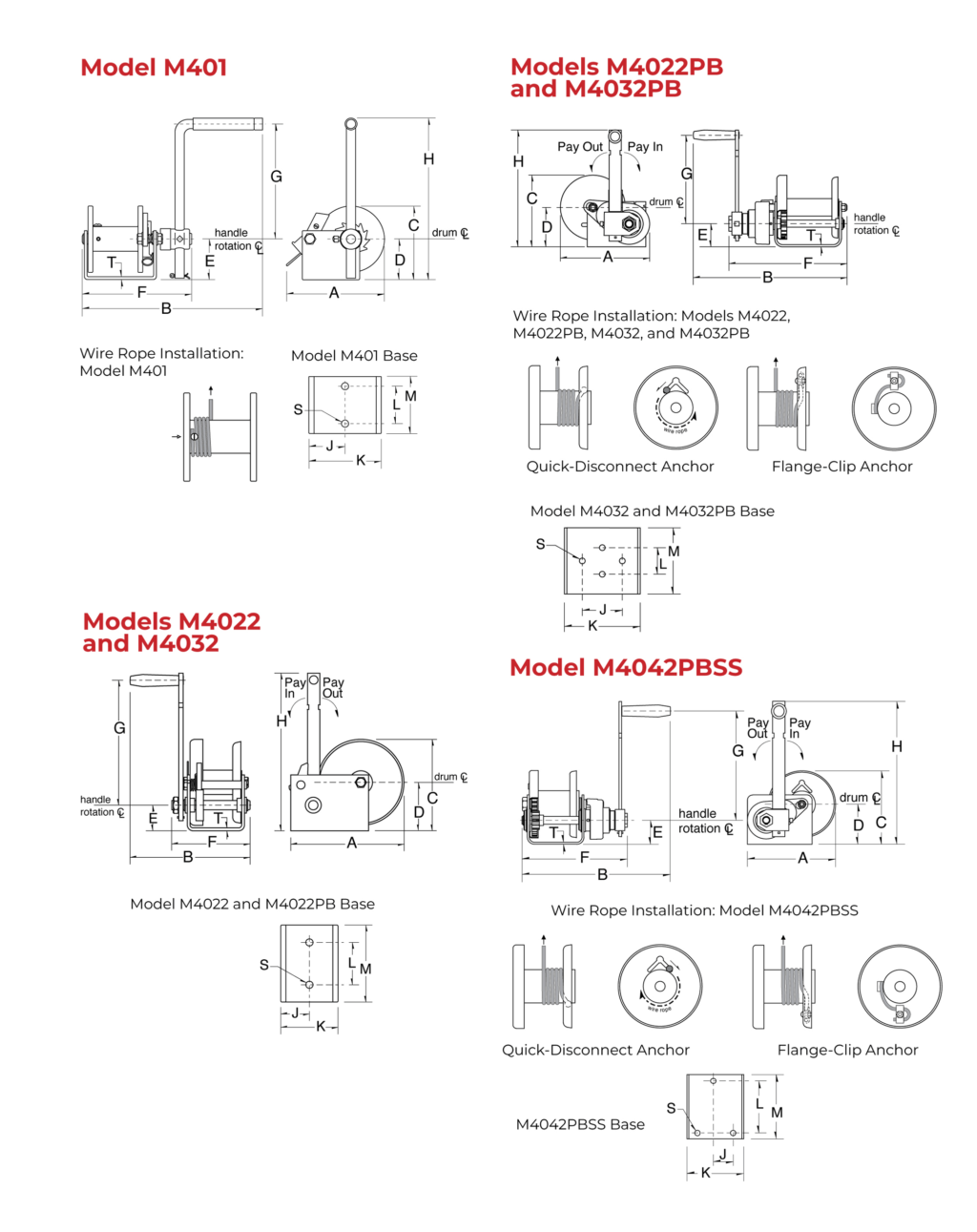

Dimensions

Models M401, M4022, M4032, M4042

| Spur Gear Hand Winches — Metric Dimensions | |||||||||||||||||

| Model No. | Drum Dia. | Flange Dia. | Drum Width | A | B | C | D | E | F | G1 | H1 | J | K | L | M | S (hole dia.) | T |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| M401 | 38.10 | 103.12 | 69.85 | 166.62 | 268.22 | 115.82 | 63.50 | 63.50 | 147.57 | 215.90 | 268.51 | 55.63 | 111.25 | 63.50 | 88.90 | 10.16 | 4.57 |

| M4022 | 38.10 | 115.82 | 50.80 | 187.00 | 228.00 | 156.00 | 83.00 | 48.00 | 134.00 | 268.00 | 344.00 | 47.00 | 94.00 | 72.00 | 127.00 | 11.00 | 5.00 |

| M4022PB | 38.10 | 115.82 | 50.80 | 187.00 | 310.00 | 156.00 | 83.00 | 48.00 | 209.00 | 268.00 | 333.00 | 47.00 | 94.00 | 72.00 | 127.00 | 11.00 | 4.50 |

| M4032 | 38.10 | 115.82 | 101.60 | 187.00 | 277.80 | 156.00 | 83.00 | 48.00 | 183.00 | 268.00 | 344.00 | 76.00 | 145.00 | 51.00 | 127.00 | 11.00 | 5.00 |

| M4032PB | 38.10 | 115.82 | 101.60 | 187.00 | 361.00 | 156.00 | 83.00 | 48.00 | 259.00 | 268.00 | 333.00 | 76.00 | 145.00 | 51.00 | 127.00 | 11.00 | 5.00 |

| M4042PBSS | 63.50 | 139.70 | 76.20 | 211.00 | 354.00 | 176.00 | 96.00 | 58.00 | 249.00 | 267.00 | 343.00 | 37.00 | 134.00 | 127.00 | 152.00 | 10.00 | 5.00 |

Dimensions are for reference only and subject to change without notice. 1 Models M401, M4022PB, M4032PB and M4042PBSS handles are adjustable. Dimension shown is for maximum handle length.

IMPORTANT: It is the owner’s or operator’s responsibility to determine the suitability of the equipment to its intended use. Study all applicable codes, manuals and regulations. Be sure to read the Owner’s Manual supplied with the equipment before operating it.

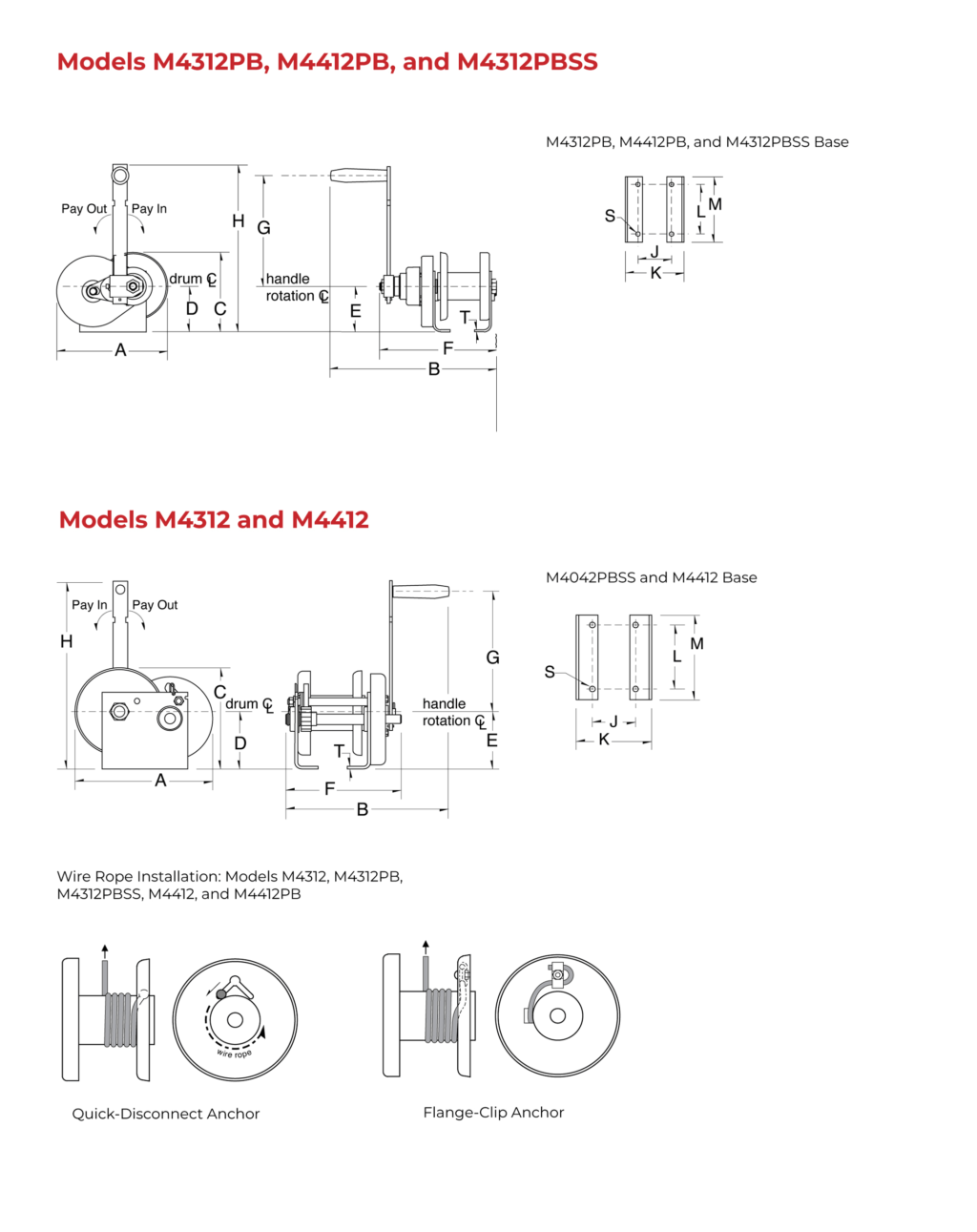

Models M4312 and M4412

| Spur Gear Hand Winches — Metric Dimensions | |||||||||||||||||

| Model No. | Drum Dia. | Flange Dia. | Drum Width | A | B | C | D | E | F | G1 | H1 | J | K | L | M | S (hole dia.) | T |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| M4312 | 63.50 | 139.70 | 76.20 | 272.00 | 330.00 | 183.00 | 101.00 | 101.00 | 210.00 | 222.00 | 339.00 | 85.00 | 134.00 | 127.00 | 153.00 | 10.00 | 5.00 |

| M4312PB | 63.50 | 139.70 | 76.20 | 272.00 | 367.00 | 183.00 | 101.00 | 101.00 | 275.00 | 268.00 | 387.00 | 85.00 | 134.00 | 127.00 | 152.00 | 10.00 | 5.00 |

| M4312PBSS | 63.50 | 139.70 | 76.20 | 259.00 | 260.00 | 183.00 | 101.00 | 101.00 | 273.00 | 267.00 | 386.00 | 85.00 | 134.00 | 127.00 | 152.00 | 10.00 | 5.00 |

| M4412 | 63.50 | 139.70 | 152.40 | 348.00 | 406.00 | 183.00 | 101.00 | 101.00 | 286.00 | 222.00 | 339.00 | 161.00 | 210.00 | 127.00 | 152.00 | 10.00 | 5.00 |

| M4412PB | 63.50 | 139.70 | 152.40 | 348.00 | 443.00 | 183.00 | 101.00 | 101.00 | 351.00 | 268.00 | 387.00 | 161.00 | 210.00 | 127.00 | 153.00 | 10.00 | 5.00 |

Dimensions are for reference only and subject to change without notice. 1 Models M4312PB, M4312PBSS and M4412PB handles are adjustable. Dimension shown is for maximum handle length.

IMPORTANT: It is the owner’s or operator’s responsibility to determine the suitability of the equipment to its intended use. Study all applicable codes, manuals and regulations. Be sure to read the Owner’s Manual supplied with the equipment before operating it.