BTS Mongoose Vehicle Recovery Tow Strops

BTS Mongoose Heavy Duty Tow Strop is a 12 strand UHMwPE tow rope designed for industrial and light vehicle and 4x4 vehicle recovery.

The Mongoose vehicle recovery strops come fitted with a heavily protected soft eye splice in each end and feature a tight heavy duty HT Nylon cover to minimise ingress of dirt and assist cleaning.

Features

- Ultra high strength to weight ratio

- Lightweight and flexible to reduce the risk of back injuries and assists on site handling

- Low elongation

- Minimal re-coil and kinetic energy at break

- Traceability (durable 1/D tags)

- Reduced hand injuries i.e. no fish-hooking like wire rope

- Heavy duty tight HT Nylon cover to minimise ingress of grit and assist cleaning

- Highly resistant to wear and flex fatigue

- Strops to 500 Tonne

- Certified to tonnage rating

- Available on request complete with marine grade round thimble

- Colour coding by application available on request

Range

| Eye Size(mm) | Approx. unit weight of completed strop (kg) | ||||||||

| BreakForce (Tonne) | Finished Diametre (mm) | 1-3m | 6m+ | 1m | 3m | 6m | 10m | 15m | 20m |

| Fully machine braided cover to body & eyes | |||||||||

| 30 | 32 | 300 | 600 | 0.8 | 2.3 | 4.5 | 7.0 | 10.5 | 14.0 |

| 50 | 38 | 300 | 600 | 2.0 | 4.0 | 6.5 | 10.0 | 15.0 | 20.5 |

| 70 | 44 | 300 | 600 | 4.5 | 7.5 | 13.0 | 17.0 | 28.0 | |

| 100 | 48 | 300 | 600 | 6.0 | 12.0 | 15.5 | 29.5 | 34.0 | |

| 150 | 65 | 300 | 600 | 8.0 | 14.5 | 24.0 | 36.0 | 47.0 | |

| 200 | 75 | 300 | 600 | 18.3 | 30.5 | 45.5 | 61.0 | ||

| 250 | 78 | 300 | 600 | 22.2 | 37.0 | 55.5 | 74.0 | ||

| 300 | 82 | N/A | 1000 | 26.1 | 43.5 | 65.0 | 87.0 | ||

| 350 | 86 | N/A | 1000 | 30.6 | 51.0 | 76.5 | 102.0 | ||

| HD Fire Hose cover to body & eyes | |||||||||

| 400 | 92 | N/A | 1000 | 35.1 | 58.5 | 87.8 | 117.0 | ||

| 450 | 102 | N/A | 1000 | 39.6 | 66.0 | 99.0 | 132.0 | ||

| 500 | 108 | N/A | 1000 | 44.4 | 74.0 | 111.0 | 148.0 | ||

Gross Vehicle Weight (GVW)

| DISTRESSED VEHICLES - GVW* | HILL OR GRADIENT TOWING - GVW* | |||||

| Mongoose BreakForce (tonnes) | Towing from general muddy, slippery conditions | Towing from Medium bogged position in mud | Towing from Heavy to Extreme entrenched position | 6° incline 1m Gradient over 10m distance 1:10 | 11° incline 1m Gradient over 16m distance 1:6 | 18° incline 1m Gradient over 4m distance 1:4 |

| 30 | 60 | 30 | 20 | 120 | 64 | 41 |

| 50 | 100 | 50 | 35 | 201 | 106 | 68 |

| 70 | 140 | 70 | 50 | 281 | 148 | 95 |

| 100 | 200 | 100 | 70 | 401 | 212 | 135 |

| 150 | 300 | 150 | 100 | 602 | 318 | 203 |

| 200 | 400 | 200 | 140 | 803 | 424 | 271 |

| 250 | 500 | 250 | 170 | 1004 | 529 | 338 |

| 300 | 600 | 300 | 200 | 1204 | 635 | 406 |

| 350 | 700 | 350 | 245 | 1405 | 741 | 474 |

| 400 | 800 | 400 | 280 | 1606 | 847 | 541 |

| 450 | 900 | 450 | 315 | 1807 | 953 | 609 |

| 500 | 1000 | 500 | 350 | 2007 | 1059 | 676 |

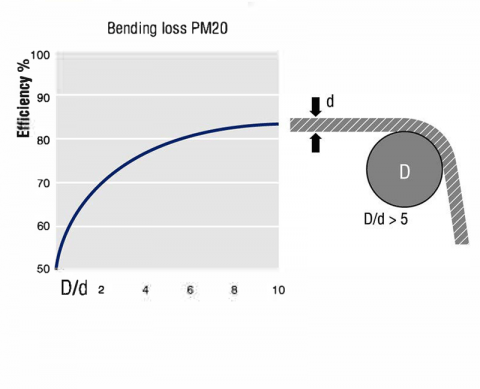

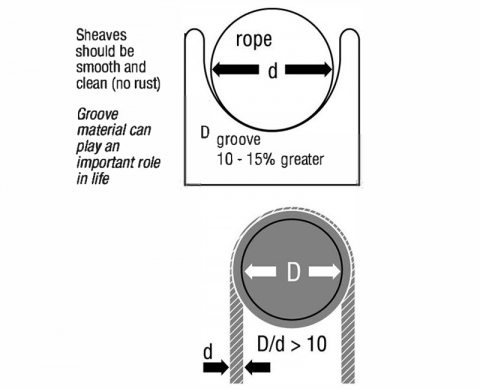

Rope properties; static bending

Rope properties; bending fatigue

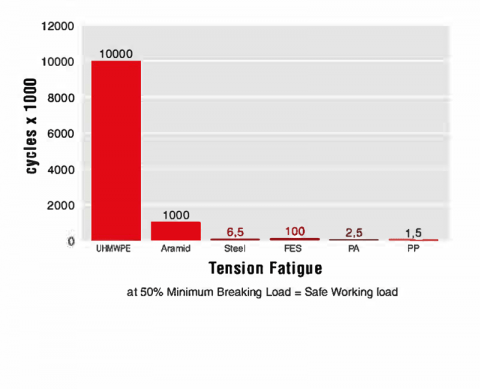

Rope properties; tension fatigue

Bending fatigue

| Fibre:Type | Description | Specific Gravity | Sensitive to | Resistant to | Heat Reaction | Strength & Elongation |

| NYLON (Polyamide) | Continuous Filament | 1.14 | Strong acids and oxidising agents, soluble in formic, sulphuric acids and phenolic compounds | Alkalis, alcohols, esters, hydrocarbons and most bleaches | Softens 229°C Melts 152°C | Elongation Dry 40%. Wet 35%. 90-95% strength ratio wet/dry |

| UHMWPE Ultra High Molecular Weight Polyethylene (UHMWPE) | Continuous Filament | 0.97 g/cm3 | Strong oxidising agents, Chlorosulfonic & Nitric acids at high temperatures. Slightly affected by Sodium Hydroxide (pH>14) | Most acids & alkalis, cold alcohols, ethers, esters, ketones & bleaches | Softens 144°C Melts 152°C | Equivalent wet/dry strength ratio. Elongation 4 % at Break |